Efficiency In Marking - The English Woodworker

I’ve stated it many occasions (although I’m positive I’m on the fallacious web page).

I consider that hand instruments are probably the most environment friendly arrange for the person maker.

And never simply the hobbiest.

Should you’re building one-off items for shoppers then hand instruments are nonetheless the place it’s at.

Most that may disagree lack a radical information of utilizing hand instruments.

I"ve numerous causes, and lots of exceptions. However I gained’t go in to all of them right here.

I simply needed to think about one space of working by hand that may result in terribly inefficient work. And that’s marking out.

Marking out by hand is a really totally different animal to taking a machine or energy software strategy.

For this reason I differentiate the 2.

It’s not snobbery, it’s that if I got down to do one thing on machine I take a unique strategy to beginning out by hand.

My machine strategy assumes items are sq., flat and common. Measurements are fastened numbers.

The hand strategy doesn’t look after numbers. As soon as issues are to tough dimension I’ll not often care to know a size or angle particularly.

Like I’ve stated, hand instruments are probably the most environment friendly for one off stuff.

However I’m not going to fake I don’t dread the monotony of marking issues out.

In one piece there’s nonetheless going to be a number of of the identical joint.

In case your desk has 4 legs, then that’s at the least eight mortice and tenons.

And I gained’t even rely the joints once I’m beginning a chest of drawers.

I actually don’t need to should mark every little thing out individually.

Having a poor strategy to marking out has an identical impact to a scarcity of sharpening routine.

It halts your momentum.

Hours spent laying out some strains on wood doesn"t really feel productive or motivating. And with poor marking routine every thing else that follows will grind to a crawl.

A primary marking rod

Time To Make A Marking Rod

This is the reason I’ll typically spend time in a venture to create some type of marking information, or rod.

Rods are so simple as they get.

A little bit of stick to some key measurements laid out you can switch onto a number of elements. However a easy marking rod could be a big time saver.

And when you collect how they work, you"ll be able to assume up customized options for many tasks, that not solely see you flying by way of the marking out, however guarantee accuracy.

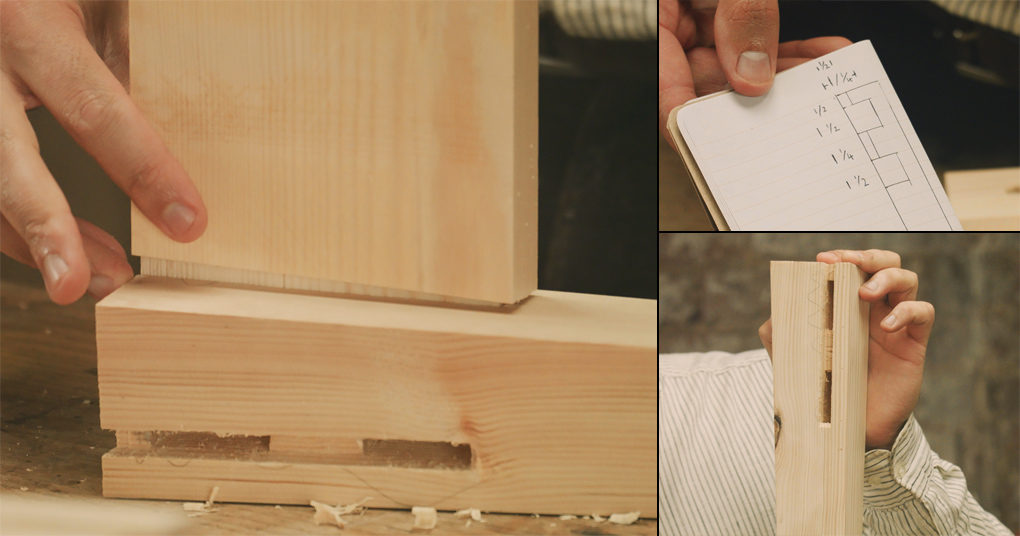

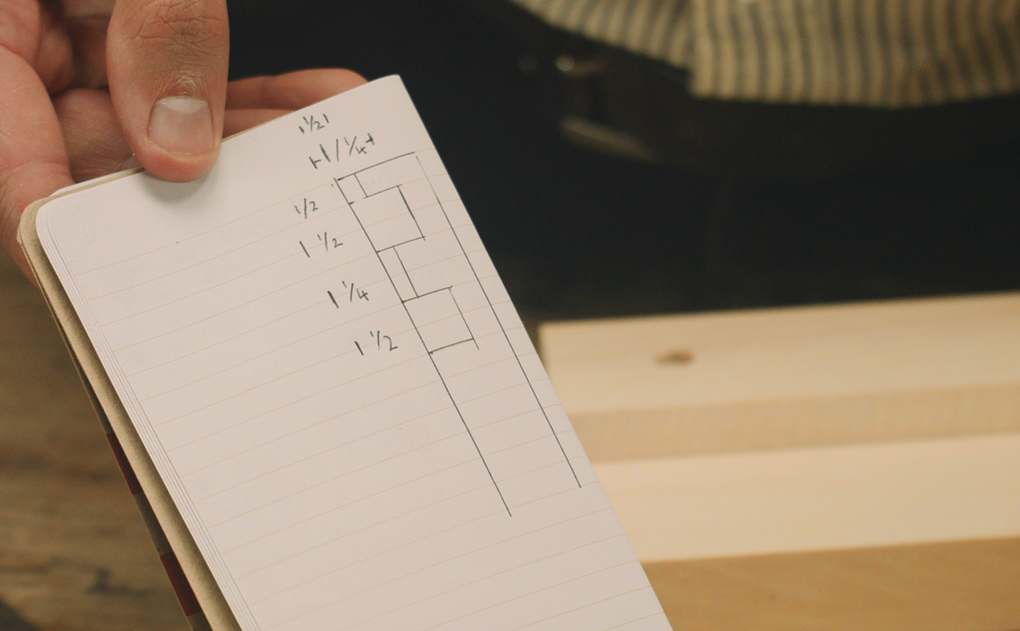

Double mortice & tenon – joint format with haunch

The Mortice & Tenon Instance

Let’s return to these 4 desk legs that want eight mortices.

They’re double tenons (that’s completely regular).

Let’s mark them out with a ruler.

It"s a must to mark the haunch, the primary mortice the bit that divides the mortices after which the second mortice.

Now you might want to mark the haunch depth, know the mortice depth, and gauge the positioning and width on the leg.

Then do it seven extra occasions…

How correct do you assume you’re being with that ruler?

With the marking all executed, let’s chop them.

Each inaccuracy from the marking out is now transferred into the piece.

However I suppose since we’re working by hand we’ll match every of the tenons individually anyway…

You"ll be able to shortly see how time begins to stack up, and why hand instruments are deemed sluggish.

Inaccuracies and variation in your first marks imply that additional time must be spent at each job that follows. To get issues to suit individually.

Making the fenced marking information.

Evolve The Primary marking Rod

Now let’s get our head out of our arse.

We spend 5 minutes and knock up a ‘Morticing Marking Rod & Information’ all-in-one particular. (Or fenced marking information, whichever you discover most catchy).

That is what I utilized in our Corridor Table.

The strategy for making one varies relying on the dimensions of joint it’s for. This was fairly an extended joint so is a little bit of a worse case state of affairs. It nonetheless solely took a tad longer.

Identical to a marking rod, you lay out your measurements for every part of the joint to allow them to be transfered shortly and persistently to every leg.

Utilizing the fenced information to shortly find, and precisely cut the mortices.

What’s particular right here although is that this information has a fence.

The fence is thicknessed exactly so we will find our chisel towards it.

Now we have now no marking to do for the lengths or width of the joint.

In addition we will work our chisel alongside the fence to make sure the joints are lifeless straight and correct.

So to prime all of it off, every joint is nearly similar.

Which means our tenons can now all be cut the identical with little or no fettling.

Mortices are cut precisely and good and straight.

Efficiency In Prepping

We can get all of this accuracy and velocity even on very roughly, inaccurately hand prepped materials.

All of it works simply by understanding face and edge marks.

By referencing every thing off pre-decided faces I didn’t even prep the again of the desk aprons in any respect.

They’re nonetheless tough sawn, and the legs have been well out of sq..

Don’t stop there… evolve the marking rod on your wants. This one helps you drill sq. as you find your holes.

So Many Prospects

This is only one instance of evolving a marking rod.

I make some sort of hybrid – multi-perform factor for many tasks.

Later within the desk construct we’ll have a ‘Mark Quick & Drill Square’ variant for getting us by means of the drawboring.

You’re in all probability considering it’s simpler to skip making the guides.

However when you’re building alongside I urge you to provide them a go.

You"ll save time, I promise.

thirteen;

Komentar

Posting Komentar